Jeff wrote... "I was ecstatic when I received a text from Cameron inviting me to float down the Thornapple River with Allen Campbell on the oars. It felt like a long time coming. After years of working with Cameron from afar, with emails and texts, countless collaborations, we had never met face-to-face. Now, I was going to have a day on the water with him, exploring a river I hadn’t yet fished, sharing a boat with a veteran guide, and doing what I love most: fly fishing and drifting down a river.

For years, we had tried to make this happen, only for prior obligations to get in the way. But this time, the stars aligned. Not only would I finally put a face to the name, I’d experience a piece of water that felt both new and promising."

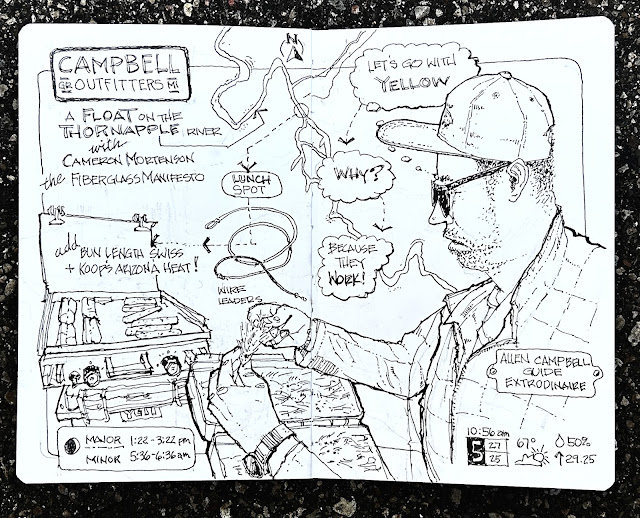

"As an Industrial Designer, one of the most rewarding parts of my job was creating journey maps

—

visual stories of how people interacted with a product, or how they

went thru their day getting their job done captured through words and

sketches. Sometimes it was as simple as words scrawled on Post-its,

arranged in a sequence. Other times it was rich illustrations capturing

moments, thoughts, feelings, and discoveries. The goal was always to

understand a person’s experience more deeply — why they acted, what they

felt, and how design shaped their journey.

Today, in retirement,

I call this story sketching, and it goes hand in hand with fly

fishing. Both are about paying attention. Both require being present.

Both teach patience and reward practice.

With a fly rod in one

hand and a sketchbook in the other, I can capture moments that a camera

might miss: the sound of a rising fish, the way morning mist rests just

above the surface of the water, the camaraderie between friends. The

pages of a sketchbook carry the sights, the smells, the feel of a day on

the river, moments captured with a pen, shaped by emotion, and shaped

by experience.

After a memorable float down the Thornapple River,

saying goodbye to Allen and Cameron felt bittersweet. Driving home, I

reflected on the moments of the day, the fish we missed and the fish we

landed, the laughs shared between strokes of the oars, the quiet spaces

between conversations. The incredible shore lunch.

I

pulled over, opened my Field Notes® notebook, and jotted down thoughts

and ideas before they could slip away. The next morning, I pulled out

my sketch book and began working. What I love about this process is how

words and images intertwine. Simple drawings capture moments a camera

might miss. Compositional elements guide the viewer’s eye across the

page. Sometimes the layout evolves into a multi-panel scene, almost

like a graphic novel. Sometimes it doesn’t work as intended, and that’s

okay. It’s about trying, practicing, and growing.

Through story

sketching, I can capture moments that photographs can’t. The sound of

the river whispering past the boat. The feel of a fly line unfurling

across the water. The quiet thrill of seeing a fish rise, the pull on a

streamer and the straightening of the line, and the sound of a reel

singing as the line goes tight. A photograph can freeze a scene, but a

sketch can carry its heartbeat. Storytelling in this way goes beyond

words and images, it’s about emotion, atmosphere, and remembrance. Its

about translating sights, smells, and textures into moments that can be

felt long after the trip has ended.

Drawing people has never been

my strong suit. But like fly fishing, it’s a discipline that humbles

and inspires. Day after day, I practice — doing quick studies and

mastering the lines and gestures that make a person feel real. Viewers

notice when something is off, and that pushes me to try harder, to learn

more.

For

me, the best moments aren’t just about the fish we land or the places

we travel, it’s about how we remember them. Story sketching has become

more than a hobby; it’s a way to relive moments long after the lines

have been drawn, the watercolor washes dried and the pages have been

closed.

Through ink and paper, I can capture more than a scene — I

can capture its soul. The sound of a rising fish. The quiet

anticipation between casts. The friendly chiding from the guide,

sharing stories as the river flows by. A photograph can freeze a moment

in time, but a sketch can preserve its movement, emotion, and

atmosphere.

Each trip adds another page to the journal, another

chapter to the adventure. Story sketching doesn’t just document where

I’ve been, it reminds me why I go. It blends the sights, sounds, and

feelings of a day on the water into a language that speaks long after

the trip has ended.

So, if you’re planning an adventure — a day

on the river, a journey down a trail, or moments worth remembering, I’d

be honored to join you as a "Visual Trip Reporter". Together, we can

capture the story that only your adventure can tell, one line, one

stroke, one moment at a time. After all, every trip has a story worth

telling. And every story deserves a sketch."