The name Struble should resonate to everyone from hobby fly rod builders, custom builders, and to long standing fly rod companies. They have been on the map for decades and what began in 1974 with Glenn Struble, and continued with Jeffery Pentecost, is now in new hands with Steven Van Winkle (who you may know from Shopkeeper Fly Rods) and his partner, John Smith.

As I was putting this T.F.M. post together, I asked Steven if he

had a shop photograph of he and John together and he responded

back that

"Everything has been such a whirlwind and we’ve known each other forever, I

guess we never even thought to take a picture yet."

I guess that's a good place to be at when you've taken over a heritage shop with a longstanding history of excellence and many exciting developments to come in the future.

There's a lot to

unpack here and the half dozen or so questions that I sent Steven

awhile back

were returned with a whole lot more. This is Steven's story and what

he wrote really gives you a lot of background on what lead him to take

on Struble.

You might want to refresh your

coffee before you continue on. Steven gets wordy...

Steven Van Winkle wrote...

"I, like many others, was raised fishing. Growing up in Nebraska, that

meant bass and healthy doses of catfish, bullheads, and carp with an

occasional excursion to one of the stocked State trout lakes.

My dad got me into fly fishing when I was fourteen with a trip to the north

fork of the Coeur D’alene River in Idaho. Trying to whip #16 Renegades to

sipping trout was at once extremely frustrating but incredibly interesting.

Where I came from, we chucked all sorts of nastiness to the bottom of ponds

and waited for the rod tip to bounce. While I confess to a certain nostalgia

today for sitting on those banks and watching those tips, that first fly

fishing trip to Idaho made going back to Nebraska and dough bait awfully

tough.

Because of that trip, after high school, a friend and I moved to Bozeman to

pursue everything outdoors Montana offered that Nebraska did not. Of course,

in 1985, Bozeman was much different than today and I learned to tie flies

while tending a gas station at night. I also bought my first fly rod; it was

graphite, had a foam grip, plastic seat, and most important of all, it was

cheap. In my memory, that 9’ six-weight cast pretty well, but like most

initial purchases in anything, I wanted to step-up.

That was a rude awakening. In ’85, not many people fly-fished, even in

Bozeman. Neither were there many shops and few choices for rods, especially

to the newly-initiated making $3 an hour pumping gas. I discovered almost no

rods between $19 and…Orvis. Eventually, my dad bought me a very nice Garcia

I still have to this day, but that was my first education in financing a

sport I loved.

I worked at a sporting goods store in Lincoln, Nebraska after moving home

from Montana to go to college. Again, this was 1987 and this store had

too-soon gone all-in for fly fishing and was still stinging from thousands

of dollars of inventory they essentially couldn’t give away to the avowed

bait-and-plastics fishers of the Midwest. It was all tossed downstairs a few

months before I started.

I found a pile of it in the darkest corner of the basement while looking

for something else; it truly was like finding treasure. Boxes and boxes of

fly-tying material and fistfuls of rods. I bought everything I could and the

store was still so hateful toward fly fishing they practically gave it to

me. Along with a couple garbage sacks-full of material, a 7’6 four-weight

Orvis “Brook Trout,” and a Leonard Golden Shadow 7’6 six-weight graphite

rod, I bought the blanks they had tried to discard.

I knew nothing about building a rod. The first I ever attempted was from

that stash: An Orvis kit for their 7’9 five-weight “Far & Fine”.

The kit came with everything, including varnish and seat and I began in my

basement with notched cardboard box and phone book tensioner and started

spinning.

It was hideous. I had visions in my head of glossy, gleaming graphite

goodness but ended with some Chernobyl-looking monstrosity. Besides all the

common mistakes of most beginners, I managed to convince myself red nylon

thread wraps would look gorgeous with blue nylon tipping. I’m pretty sure if

Ipecac won’t induce vomiting, the next step is to look at that rod. The

other blank I bought was a Sage 9’ six-weight Graphite II. I still have both

rods but the only component I remember buying was a ubiquitous Struble U1

with walnut insert.

Eventually I re-did both rods to look more like fly rods should but my

first time building taught me another lesson beside the fact that making

rods and making beautiful rods were two very different things. I learned

that building rods was far cheaper than buying factory rods. Along with

typically better components and wide customization possibilities, it just

made better sense to build rather than buy. I also learned I really loved

doing it.

I moved back to Bozeman after college and getting married and pastored a

church there for a little over twenty-five years. Between ministry and kids,

rod building was more an occasional hobby. I started picking up the pace on

building about five years ago. Fly rods are almost mystical to me and I love

building them, but it is a terminal hobby unless you can sell a few along

the way.

Because of this, Shopkeeper Fly Rods was born (“Van Winkle” in Dutch

translates roughly as “shopkeeper,” at least that’s what my parents told

me). I never meant to be a full-time gig as it’s more the vehicle

through which I can afford to keep making rods for me and for others, but I

make them nonetheless. Ever since that first foam-handled fly rod I bought

back in the mid-80s, I’ve remembered what it’s like not to be able to afford

nice rods. The tagline, “Rods for the Rest of Us” is meant to reflect that

memory and is one of the fundamental ideas behind Shopkeeper, namely, a goal

to keep the prices as reasonable as possible. I know any number of guys who

make nicer rods, so selling as many as I have is very gratifying.

I took a position at a college in Boston in 2019. I’m here nine months

building rods and (trying) to fish New England, but get early spring and

summer in Bozeman with nothing to do but fish. Kind of a best of both worlds

scenario that didn’t actually happen this last year because of Struble.

The acquisition of Struble is, indeed, the dumbest of dumb luck. I was

looking for an agate guide back in January and went to the Struble website

which had a notice up saying they were going to liquidate inventory in

March. Whenever I hear “Struble”, I think of reel seats and always thought

there was something missing in the rod building world since they stopped

making them. Eventually we get used to most anything and about the time I

had grown accustomed to Struble not making reel seats, it appeared to be

going out of business completely. I set a reminder to check back in

March.

Checking back in March, the notice said the liquidation was now set for

April. By this time, we had gone back to Bozeman because of the coronvirus

pandemic, and I was teaching online. I set another notice.

In April, the notice was a little different. I don’t remember the exact

wording but it basically said it was for sale and that “Serious Inquiries”

could be directed to a Struble email. I did nothing for a few days, but

eventually curiosity got the best of me and I emailed with what was “Serious

Curiosity,” if not a serious inquiry. That was April 4.

Jeff Pentecost (previous owner) responded right away, but his response

wound up in the trusty spam folder and I didn’t see it for two weeks. When I

did, I wrote him back asking more details on his initial information which

essentially said the entire company was being sold. Suffice it to say I had

no business buying a business but after a couple more exchanges, Jeff and I

talked on the phone and he told me the abbreviated version of the entire

Struble story up to why he was wanting to sell at this time. For someone who

knew Struble when it dominated the globe in reel seat manufacturing, it was

at once fascinating and unfortunate.

Jeff is a doctor and was planning to spend more time in his profession and

simply didn’t have the schedule anymore to continue the business. He was the

sole craftsman for the agate guides and, while he loved making them,

dedicating the little time he had to producing them wasn’t making much

sense.

His price for the company was very reasonable. I still had no business

buying one, so I called a lifelong friend in Billings to see if he’d be

interested in helping finance the venture. John’s a retired deputy with the

Yellowstone County Sheriff's Office who owns a business in Billings and I

knew he was looking to do something else. Despite not being a rabid fly

fisher, he loved the idea and hopped on board.

Part of the dumbness of the story is how COVID-19 had made a number of

suitors for Struble either nervous or back out of interest in purchasing

either inventory or the entire company. And while we had the ability to

offer Jeff what, for us, was significant money, it still wasn’t close to the

asking price. When I wrote him with the offer, I told him we weren’t trying

to be captains of industry or used car negotiators and our ultimate hope was

to get Struble back to where it needed to be, including reel seat

production. I also indicated I was interested in taking it on because of the

nostalgia I felt for Struble, which stretched all the way back to the second

rod I ever built over thirty years earlier. But, I also stressed I would

completely understand if he passed.

Four days later, to my great surprise, Jeff accepted our offer, and John

and I went to pack up the remains of Struble from a storage unit in Portland

in early June. I can’t say enough good things about Jeff Pentecost and his

graciousness with us. He has been a true gentleman and completely

transparent about the company’s history and has been available for utterly

any obscure question we have or consulting on ideas. Not only has he

withheld nothing, he has continued to find and ship inventory to us, he's

also spent time with us helping us get better at the craft of agate guides

and consulted on reintroducing reel seats.

Considering he didn’t receive his asking price, his generosity of time and

information seems to me extraordinary and is terribly appreciated. I believe

it also demonstrated Jeff’s desire to see Struble survive a precarious time

and not be parted out like it seemed it might be.

However, to my greater surprise, there was more to the inventory than Jeff

indicated. Not only were there greater numbers of items listed, there was

more seats, inserts, and equipment he hadn’t listed. One of the most

interesting things I’ve done is sifting through a couple boxes that resemble

the “Junk Drawer” everyone has in their kitchen. Jeff is a very organized

man and everything in the storage shed was neat, clean, and in its place.

But, there were a couple boxes with just “stuff” in them.

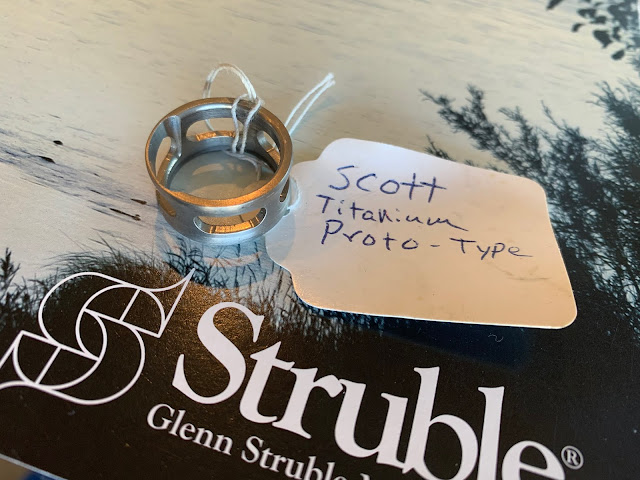

Going through those boxes was a tour through a lot of fly fishing history.

There were experimental programs and components for Sage, designs and seats

developed for Burkheimer and Tom Morgan, a titanium prototype for Scott, and

some stunning seats and woods for makers in Europe, including Maisey and

Harry Jamieson, who made rods for Prince Charles. There was also an example

of nearly every reel seat Struble ever produced along with some “alternate

universe” aluminum versions of nickel silver standards. In a forgotten junk

box in the back corner of a storage unit, was evidence of the shadow Struble

once cast over fly fishing worldwide. It was humbling to realize John and I

were now the stewards of that history.

Some of the designs we found in that box haven’t seen the light of day and

hopefully we’ll eventually have the chance to put the best of them in

builders’ hands.

What the future looks like six months from now is materially different than

when you first sent me the questions. As I said, we always wanted to explore

reintroducing reel seats. We set out to talk to machinists and start getting

ideas of what it would cost and see if the dream was feasible. We had a

couple requirements about producing seats: They will be American made,

preferably in Montana. Period. These principles were derived from a

combination of John and I believing in American manufacturing and because we

wanted to keep Struble true to its American-made DNA. I’d also seen any

number of grand, American, fallen flag fly fishing companies' names

purchased, and then imported paraphernalia sold under its name.

I certainly understand builders being economical and we have no conviction

against non-American equipment; however, we would like people to know this

isn’t an instance of a name being used simply as a vehicle to sell cheaper,

imported components. Struble seats and agate guides have always been made in

America and our non-negotiable intent is to keep it that way.

Doing that and making seats affordable didn’t look so promising after a few

conversations with local machinists. Dusty Smith at Livingston Rod Co. put

me in touch with a Montana manufacturing consultant who was incredibly

helpful. He gave us a list of manufacturers and those who know

manufacturers; from that list, we thought we had a machinist set to go in

Bozeman.

However, also from that list, John had met Wes Tuscano who owns Tuscano

Machine in Big Timber, about 50 miles east of Bozeman. With a brand new ISO

9001:2015 facility and equipment, John was impressed with Wes and his

operation. While I was hesitant at first, when the machinist we had

previously spoken to didn’t call us back about getting started, John and I

went to speak with Wes. I immediately saw this was a different operation

than our Bozeman contact; not only can Tuscano Machine machine metal, it can

3D-print and laser etch components with amazing precision.

Wes and his VP of Administration, Julie Johnson, showed us unusual interest

in the project as a whole: Resurrecting a venerable company which had

machining at its root. When describing the history of Struble, we mentioned

how foreign-made components played a role in the demise of its reel seat

business. I think this intensified their interest, as one of Wes’ passions

is seeing manufacturing in America revived.

Like John, Wes fishes but has no background in making rods, so the process

was not only one of exploring costs but also of education about rods, reels,

and some fly fishing history. As the back-and-forth progressed, Wes saw how

committed John and I were to the idea of reestablishing Struble

Manufacturing and we saw his and Julie’s interest in knowing much more about

our project than simply the bottom-line, and working together became a

genuinely enjoyable experience.

After talking with builders like Dusty, Shane Gray, Matt Barber, James

Green, and Jeff about which seat models to first reintroduce, we turned it

over to Wes hoping we could afford to initially get a couple of the four

models submitted manufactured in the first run. However, once Tuscano

Machine sent us a quote, we saw it was possible to do all four, so we

submitted a purchase order for models 1, 20, D2s, and Jeff’s most recent,

the 15LX3 with its incredibly smooth thread design. After talking more with

Shane, we switched out the D2s from the first run for a same-dimensioned,

downsized model 27 (something Struble hasn’t offered before).

We had previously agreed for whatever order we submitted, Struble could put

a percentage down with the balance paid within a designated period of time.

However, on the PO, our initial down was to be a slightly smaller percent

than what we had discussed. In the offer, I explained we were excited enough

about the possibilities that we wanted to be a little more aggressive with

our order than we first thought.

A couple days after we submitted that PO, Wes and Julie asked to have a

conference call about it. Honestly, I thought they were going to tell us we

needed to put more down; John thought the same. Because of the time

difference between Massachusetts and Montana, I was in my truck when we

scheduled the call. Once we started talking, I was waiting for Wes to ask

for more so I could offer my practiced apology for presuming to offer less

upfront than previously agreed.

That’s about when Wes said he wanted to propose he absorb the remaining

cost of the order as an investment in Struble. John started laughing with

disbelief, but I had to ask him to repeat what he said as someone had come

up to my window and distracted me at just the wrong moment to hear what he

said clearly. Wes did, and then I started chuckling with disbelief. I was

keenly aware that Struble Manufacturing with me and John at the helm was

not, technically, “manufacturing" reel seats; we were just a couple guys

placing an order for them.

Wes’ offer changed all that in an instant. John and I apologized for

laughing, and we started talking about the possibilities. Wes said he saw

our passion for the enterprise and enjoyed working with us and felt that not

only could he bring to the table some valuable skills but he felt the future

was very bright. Of course, we agreed and talking further, has only made us

more excited about what Struble can offer builders and fishers going

forward.

All along the way, from not initially thinking of inquiring, to not being

able of myself to purchase a business, to not seeing Jeff’s first response

until two weeks after he sent it, to only being able to offer less than the

purchase price, to Jeff’s generosity, to a world-class machinist and shop

offering to partner with us in the adventure, I’ll certainly credit the Lord

while acknowledging the dumbness of the dumb luck.

When you originally sent these questions, in “six months” I would have

hoped to be proficient at agate guides and possibly getting a couple models

of reel seats produced in fairly small numbers. Now, with a third partner as

our an in-house machinist, in six months I believe we’ll be offering a full

line of easily ordered agate guides in sufficient numbers for immediate

delivery, at least four models of the highest quality, along with affordable

reel seats in enough quantity to keep everyone stocked- all made in

America, all made in Montana. Additionally, we’re also talking through plans

to address other areas of need in rod building and fly fishing and talking

through some creative ideas for the future. Because we’re so excited about it, we’re working hard to make that future

arrive as quickly as possible."

Take a few minutes to check out the recently re-launched

Struble website and look

for big things coming in the near future. Follow along with the latest shop news on

Instagram.

5 comments:

Great story thanks for sharing it. I am a longtime Struble fan. So glad you are bringing it back! When Jeff took over he did a

Yeoman's job of keeping the business afloat and I continued to buy Struble products for my builds. Jeff was always a pleasure to deal with.

Great story thanks for sharing it. I am a longtime Struble fan. So glad you are bringing it back! When Jeff took over he did a

Yeoman's job of keeping the business afloat and I continued to buy Struble products for my builds. Jeff was always a pleasure to deal with.

What a great read, so awesome that he opened up like this. The transparency is really admirable, and what Struble is setting out to do is inspiring. Rooting hard for them!

Nice website, but shipping time seems a bit lengthy, to say the least. Been waiting for two weeks…

Glenn was dead by the time Dick French put me onto Juanita.

Jeff started working for she and her husband when he was very young.

They couldn’t find a good source for high figured fiddleback or what is known as curly maple. They were looking for 7 to 9 vertical inches per inch.

After a few phone calls, they were connected to a company here in Vermont and USF Red Star started the deliveries west.

Juanita was a very gracious woman, very good over the phone.

It’s like you knew her all your life!

Post a Comment